Back-Up Rings & O-Rings

Back-Up Ring Benefits

- Excellent high temperature capability and resistance to extrusion compared to other conventional polymer sealing products.

- Important for high pressure and temperature applications

- Precision manufactured from Duron® polymers enhances basic seal performance

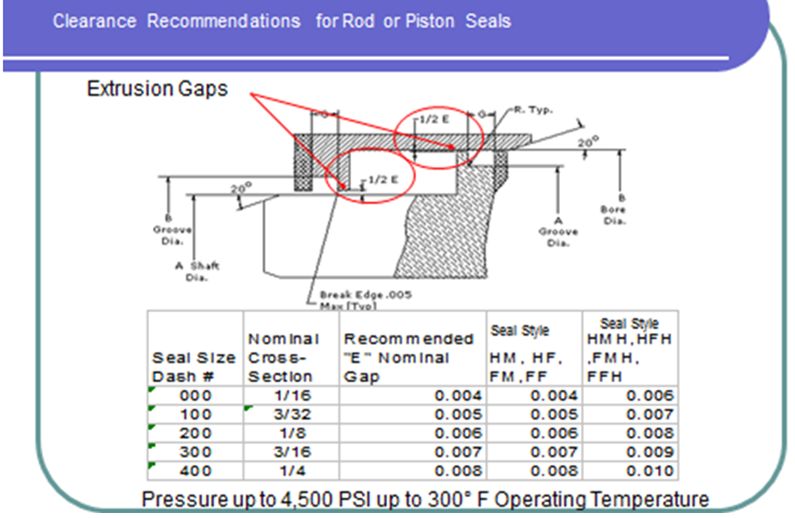

- The Diametrical Gap is defined as the clearance between the rod and bore and the housing for the seal. Illustrated below is the standard recommended “E” diametrical Gap.

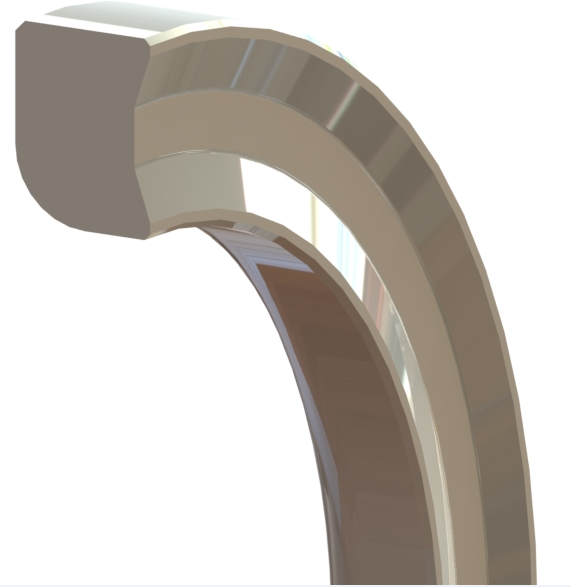

O-Ring Design

There are several backup ring configurations depending on what type of sealing device is being supported. They range from a standard uncut PTFE back-up ring per MS27595 to Dual Cammed PEEK back-up rings. For a complete proposal, submit a request for quote and we will respond, immediately.

|

Solid Back-up Ring | Solid backup rings are ideal anti-extrusion devices. This backup ring is best used when maximizing performance and in split glands when installation is not an issue. | RFQ |

|---|---|---|---|

|

Standard Duty Single Turn Ring | Standard duty single-turn backup rings are perfect for full O-Ring style glands when solid back-ups won’t install. | RFQ |

|

Double Thick Solid Back-up Ring | Double-thick solid back-up rings are used when extra high-pressure capabilities are needed in split glands. | RFQ |

|

Double Thick Single Turn Ring | Double-thick single-turn backup rings are used when extra high-pressure capabilities are needed in full-height glands and solid back-ups won’t install. | RFQ |

|

O-ring Contour Back-up Ring | Contouring the backup ring to more closely conform to the O-ring allows a double thick backup ring in a gland that would not normally support a single thick ring. | RFQ |

|

Single Cammed Back-up Ring | When pressures exceed the normal limits of the backup ring, or when the extrusion gaps are extra wide, a cammed backup ring is chosen to mechanically deform and close off these extrusion gaps. | RFQ |

|

Double Cammed Back-up Ring | Double-cammed back-up rings are used when tolerances are extra wide or when both the ID and OD of the seal gland have extrusion gaps. | RFQ |

These recommendations are guidelines only. Each sealing system must always be thoroughly tested by the customer or a qualified test lab to determine the actual high-pressure performance of the sealing system. High-pressure applications require testing that must include the maximum operating temperature at pressure and duration the seal will be exposed to in the actual application.

O-Ring Applications

- Gas Compressor

- Booster Pump

- Turbine Engine

- HPLC

- Relief Valves

- Choke Valves

Contact our technical sales staff today to discuss your application's operating, hardware, and commercial conditions to develop the best-performing seal solution.

Request A Quote Online Or Call Us At 866.429.2536