Elastomeric Engineered Seals

Custom Engineered Elastomer Seals are used when extremely low leakage rates are required. We engineer a sealing solution by combining the optimal seal design and elastomer material to meet your application requirements.

Why use an Elastomeric Engineered Seal?

- Provides extremely low leakage rates

- Provides a greater temperature range than a conventional elastomer U-cup

- Resists against compression set, and thermal shrinkage

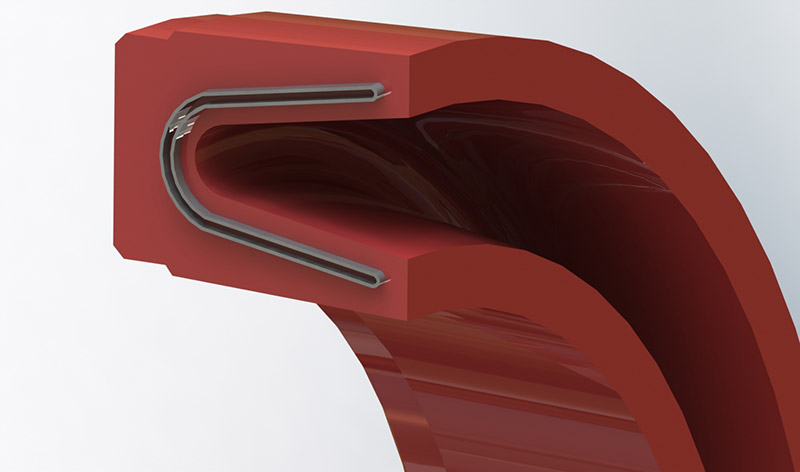

What are Elastomeric Engineered Seals?

- Can be uni-directional, or bi-directional (Elastometric O-ring seal, Tetra-Ring seal, or T-seal)

- Often utilizes a metal spring energizer to be an improvement over conventional Elastomeric Seals.

- The use of high-performance Duron® elastomeric material provides excellent chemical resistance.

- Materials commonly used are FFKM, FKM (Viton®), Aflas®

AFLAS® registered trademark of Asahi Glass CO., LTD. (AGC Chemicals)

Viton® registered trademark of DuPont Performance Elastomers LLC

Where are Elastomeric Engineered Seals Used?

- Fugitive Emission for Valve Stem Seals

- Aircraft Braking Systems

- Secondary Seals Used in Mechanical Face Seals

Contact our technical sales staff today to discuss your application's operating, hardware, and commercial conditions to develop the best-performing seal solution.

Request A Quote Online Or Call Us At 866.429.2536