Custom PTFE Engineered Seals

Spring-energized PTFE Engineered Seal Applications

Spring-energized PTFE Engineered Seal Applications

- Spring energized seals replace conventional elastomeric seals where the service conditions are beyond their operating capabilities.

- Special materials for wide applications

- Uniquely designed for your specific application

- Multiple spring configuration

- Multiple component seals

- Wide range of sizes

- Self-lubricating and can be used in dry environments

- Wide operating temperature range from -450°F to 600°F (-268°C to 315°C)

- Pressure conditions from high vacuum to high pressure (50,000 psi)*

- Excellent chemical compatibility

- Designed, engineered and machined to fit

- The spring enhances performance by :

- Allowing for tolerance variation and run-out

- Overcoming thermal expansion/contraction

- Compensating for wear to increase the useful life of the seal.

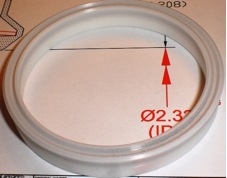

PTFE Encapsulated Seal

for FDA Service

What are Duruseal® Spring-energized Engineered seals?

Duruseals® are composed of a Duron® seal jacket and an energizer. We offer a wide range of Duron® and energizer materials, as well as configurations to satisfy your conditions and parameters. For a complete proposal, submit a request for quote and we will respond, immediately.

Contact our technical sales staff today to discuss your application's operating, hardware, and commercial conditions to develop the best performing seal solution.

*Pressure capability is based on operating temperature. Consult PSI engineering to get a recommendation or seal backup chart.

Request A Quote Online Or Call Us At 866.429.2536