Static Spring Seals

Why Use Spring-Energized Static Seals?

- Spring energized seals replace conventional elastomeric O-rings and U-cups where the service conditions are beyond their operating capabilities

- Wide Operating Temperature Range from -450°F (-268°C) to 600°F (315°C)

- Pressure Conditions from High Vacuum to High Pressure (50,000 psi)

- Excellent Chemical Compatibility

- Designed, Engineered and Machined to fit

- The spring enhances performance by :

- Allowing for tolerance variation and run-out

- Overcoming thermal expansion/contraction

Duruseal® Spring-energized Static Seals

Duruseals® are composed of a Duron® seal jacket and an energizer. We offer a wide range of Duron® and energizer materials, as well as configurations to satisfy your conditions and parameters. For a complete proposal, submit a request for quote and we will respond, immediately.

|

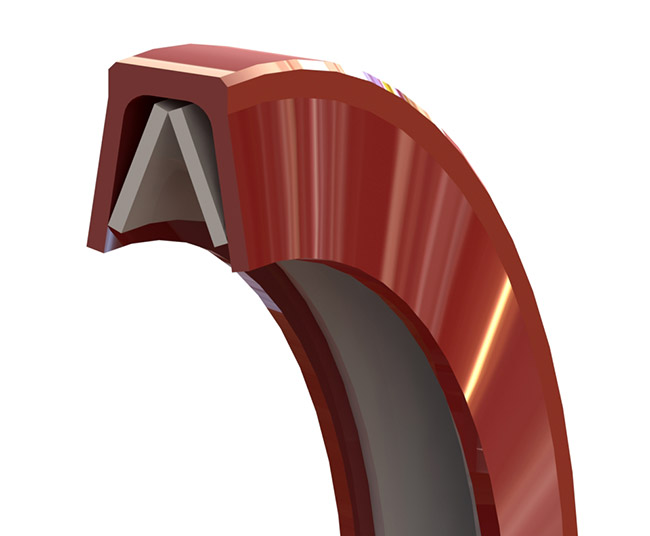

Duruseal® B: Belliville Spring Engineered Static Face Seal |

Belliville spring are engineered for small diamter face seal applications ranging from Ø0.375 outer diameter up to Ø12 inches outer diameter. The belliville spring provide a high travel spring in a compact space. |

RFQ |

|---|---|---|---|

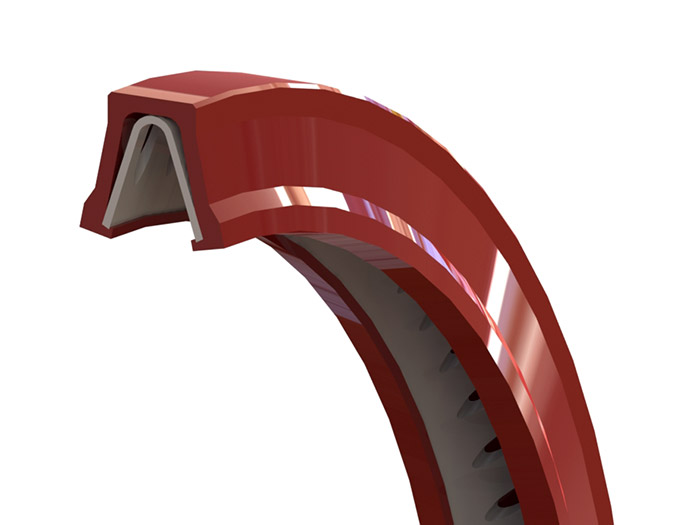

| Duruseal® HIF: Helical Spring Engineered Static Face Seal |

Helical wound spring engineered face seal design provides a high load stainless steel energizer. This spring is used to seal shaft and piston radial seals cryogenic propellant sealing. Helical springs are use for chemical hostile or extreme hot or cold sealing requirements. |

RFQ | |

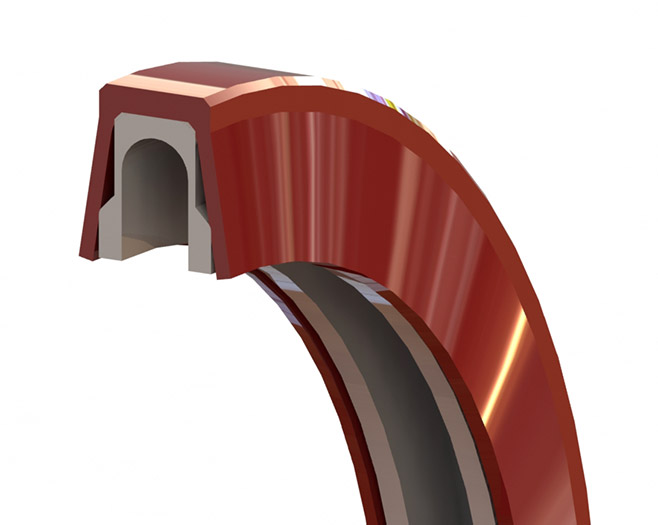

| Duruseal® DHIF: Dual Helical Wound Engineered Static Face Seal |

Dual helical wound spring outsided face design provides the highest spring load stainless steel energizer. This spring is used to seal shaft and piston radial seals. Dual helical springs are used for cryogenic applications. |

RFQ | |

| Plate Static Face Seal Retainer | Plate face seal retainer applications may be mounted in a gasket retainer. This is a replacement for a elastomeric gasket seal. The spring design is dependent on the application requirement. The gasket spring loaded PTFE seal is selected when sealing between two flat surfaces or when confirmation of the seal has been installed between two flanges is required | RFQ | |

|

Duruseal® FC: Full Contact Spring Engineered Static Face Seal | Full contact spring design provides a high load continuous stainless steel energizer. The full contact spring is used in liquid cryogenic applications and is designed to eliminate the issue of spring misalignment to the seal jacket. | RFQ |

|

Duruseal® M: Machined / Lathe Spring Engineered Static Face Seal | Machined spring engineered face seal design provides a high load continuous stainless steel energizer. This spring provides a metal barrier for the best leakage rate performance. The machined spring seal design is recommended for Helium service. | RFQ |

Spring-energized Static Seal Applications

PSI Duruseals® are used in many industries and applications. Here are a few examples:

- Aircraft Engines

- Gate Valves

- Butterfly Valves

- Ball Valves

- Brakes

- Pipe Flanges

- Fuel Manifold Seals

- Fuel Injector Nozzle Seals

- Hyraulic Servo Valve Application

- Cryogenic Valves

- Gas Compressors

- Vacuum Feedthroughs

Contact our technical sales staff today to discuss your application's operating, hardware, and commercial conditions to develop the best performing seal solution.

*Pressure capability is based on operating temperatures. Consult PSI engineering to get a recommendation or seal backup chart.

Request A Quote Online Or Call Us At 866.429.2536